Eight roll coating production lines to meet your needs

Eight roll coating production lines to meet your needs

With the popularization and application of flat roller coating equipment, its energy-saving and efficient coating methods are sought after by the majority of building materials and furniture companies. However, traditional roller coating equipment has three technical difficulties:

First, the equipment is difficult to operate and adjust, and it is cumbersome to switch paint and maintain.

Second, it takes time and effort to switch between different workpieces.

The third is only suitable for flat products with high flatness.

In order to cater to the iterative upgrade requirements of the market's product technology, it is important to choose a brand with the entire coating industry chain.

For this purpose, Boshuo Coating has innovated an automatic adjustment and maintenance-free intelligent roller coating equipment, which is used in conjunction with flexible rollers and is suitable for various flat plate-type workpieces of building materials and furniture. Through the combination of different basic production lines, high standards meet furniture (customized whole house, log decoration, office furniture, hotel furniture, high-definition minimalist); building materials (wooden door coating, bathroom coating, floor coating, science and technology board , Wall panels, external wall integrated panels, inkjet printing panels) primer, coloring and topcoat coating production requirements.

▋▍Boshuo's eight basic roller coating production lines

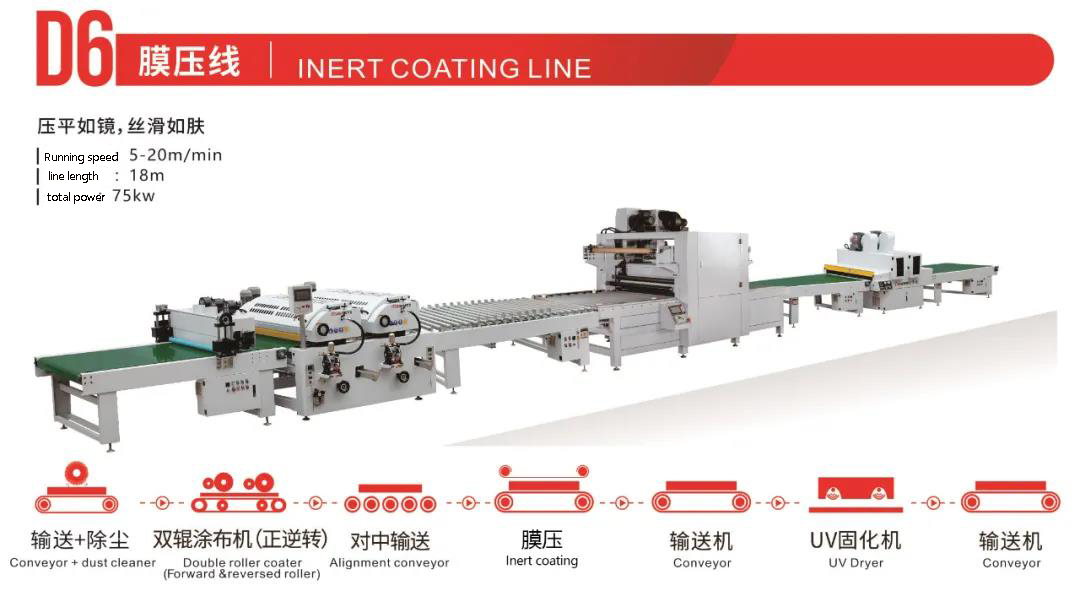

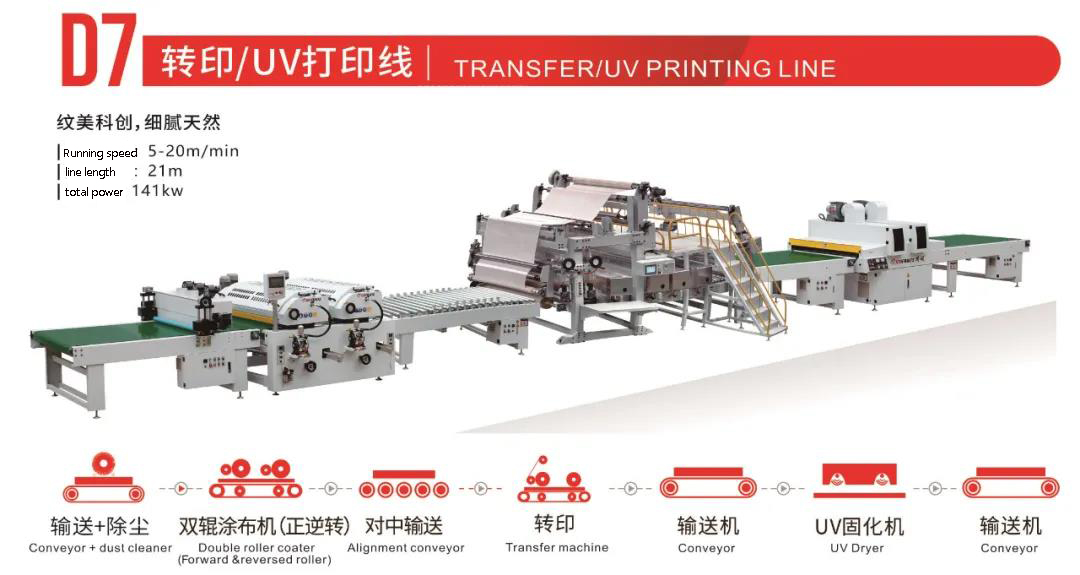

Different basic roller coating production lines are developed according to different processes: D1 rubbing line, D2 putty line, D3 roller coating line, D4 leveling line, D5 skin dumb line, D6 film pressure line, D7 transfer/UV printing line, D8 Coating line.

10 intelligent coating production lines

Each basic production line can be combined into two-bottom, three-bottom, three-bottom and one-side, three-bottom and two-side, four-bottom and one-side, four-bottom and two-side, five-bottom and three-side, and other intelligent coating production line applications according to different process requirements:

L1UV primer base roller coating production line

L2 flat groove/buckle line wooden door UV roller coating production line

L3 American Cabinet UV Roll Coating Production Line

L4 Panel Furniture/Wooden Door Standard Roll Coating Production Line

L5 plate bathroom/cabinet UV primer roller coating production line

L6 triamine board/veneer veneer film pressing and curtain coating production line

L7 high-definition board coating production line

L8 wood veneer panel high gloss/matt/skin feel roll coating production line

L9 Kechuang decorative panel 3D inkjet printing production line

L10UV transfer plate coating production line

Intelligent control function of Boshuo roller coating production line:

√ One-key start and stop: The centralized console interface can start or stop any device on the production line

√ One-key thickness adjustment: The interface of the centralized console can adjust and set all the functions of any device on the production line

√ Failure pause: automatically stop with a certain logical failure

√ Simulated display of paint consumption: The interface of the centralized control console can display the simulated consumption of paint for each equipment of the production line

√ UV energy monitoring: The operation interface of the centralized console can display the simulated value of energy consumption of each light source of each UV curing equipment in this production line, and coordinate according to the simulated value

√ Recipe storage: The centralized control console has the parameters corresponding to the different processes of the production line

√ Capacity display: The centralized console interface can display the capacity within the set time period and has statistical functions

√ Consumables use and maintenance reminder: The interface of the centralized control console can display the usage time of the consumables of each equipment of this production line and prompts for replacement, and also has maintenance reminders for important accessories

√ Intelligent adjustment: The process formula can be automatically obtained according to the scanning equipment (thickness detector, QR code scanning, etc.) to obtain material information

√ Paint quantitative setting: according to the paint quantity set by the material, the equipment of this production line automatically matches the parameters

√ Intelligent graphic display: In addition to data statistics, the production line has online graphic display

√ Intelligent maintenance: remote maintenance guidance can be performed online

√ Intelligent monitoring: the actual operating status of the entire line can be monitored through the camera

√ MES docking: the entire line of equipment data can be docked with the customer's MES system

评论

发表评论